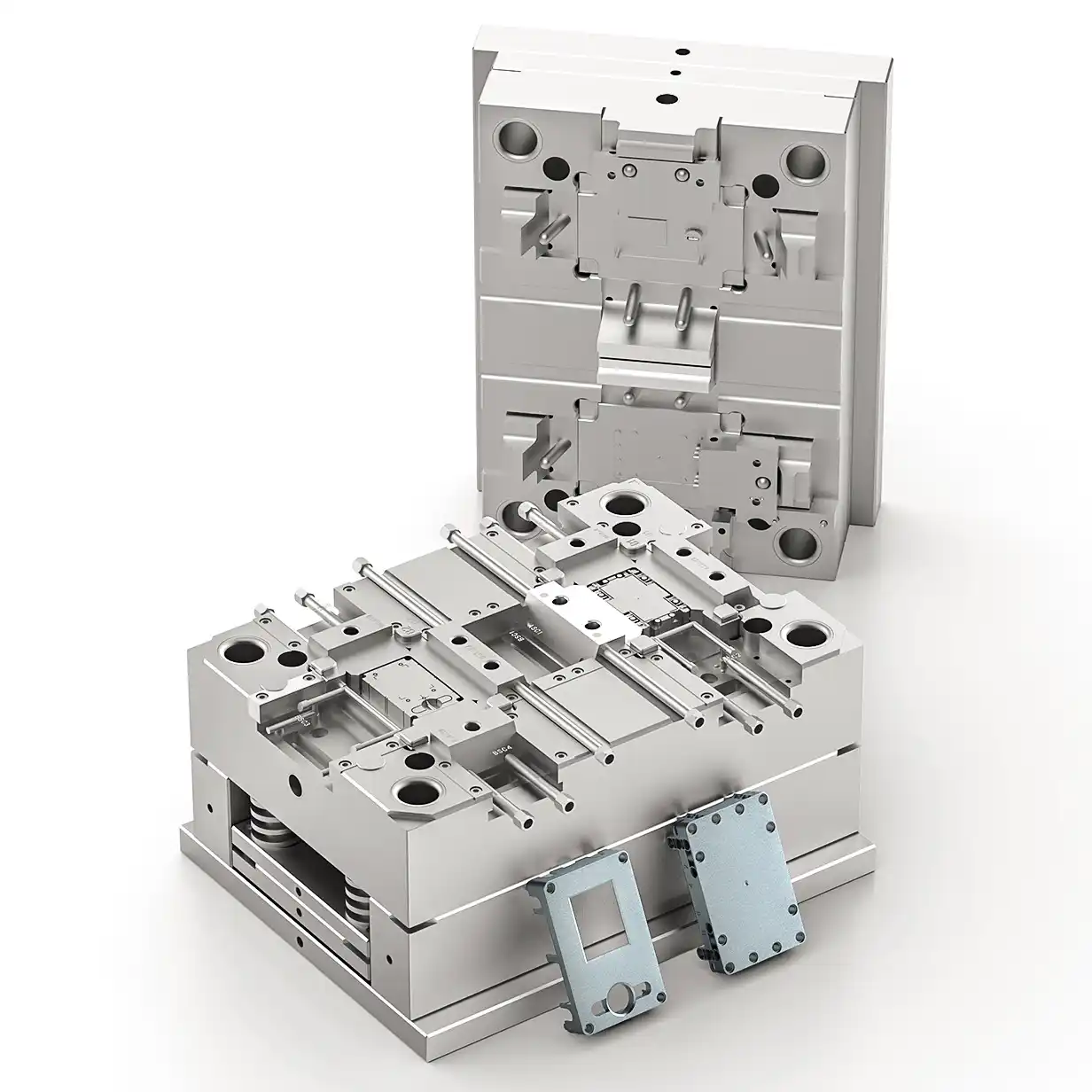

Professional ABS injection molding services for robust, impact-resistant components. We specialize in high-volume production of ABS parts with excellent mechanical properties, dimensional stability, and cost-effective manufacturing for automotive, electronics, and consumer goods industries.

Discover the key features that make ABS ideal for injection molding:

Excellent toughness and durability for demanding applications

Maintains shape and size under various conditions

Superior surface quality with excellent aesthetics

Economical material with excellent processability

Our optimized ABS injection molding process ensures quality and efficiency:

ABS pellets are dried at 80-85°C for 2-4 hours to reduce moisture content below 0.02%

Molten ABS is injected at 220-250°C with mold temperature maintained at 50-80°C

Controlled cooling ensures proper crystallization and dimensional stability

We offer various ABS grades to meet different application requirements:

ABS injection molded parts serve diverse industries with unique requirements:

Key advantages of ABS injection molding for your projects:

Comprehensive quality control ensures perfect ABS injection molded parts:

Detailed specifications for our ABS injection molding services:

Common questions about ABS injection molding:

Get a free quote for your custom ABS injection molding project. Our team of experts is ready to help you achieve high-quality parts with fast turnaround and superior performance.

Professional CNC machining and custom parts manufacturing services, meeting your precision machining needs with rapid delivery of high-quality components.

© 2025 Partsproto | All rights reserved.