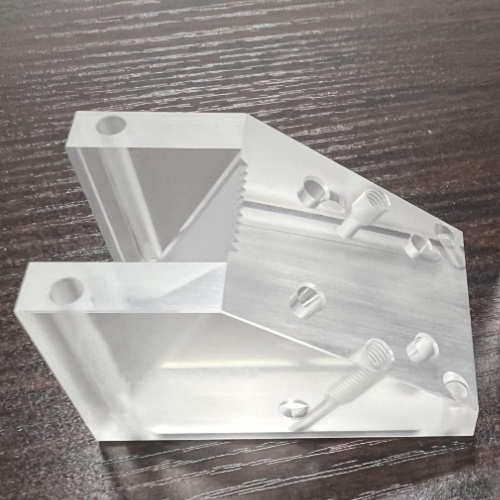

Expert manufacturing of custom polystyrene components with excellent dimensional stability and surface finish. From packaging solutions to consumer products, we deliver quality PS parts that combine aesthetics with functionality.

Best value for production

High gloss finish possible

Quick turnaround time

Choose from our comprehensive range of polystyrene grades:

Optimize your parts with our comprehensive design features:

State-of-the-art processes for polystyrene parts:

Serving diverse sectors with specialized PS solutions:

Our commitment to environmental responsibility:

Comprehensive quality control measures:

Comprehensive assistance throughout your project:

Contact our experts today for a consultation and quote

Professional CNC machining and custom parts manufacturing services, meeting your precision machining needs with rapid delivery of high-quality components.

© 2025 Partsproto | All rights reserved.