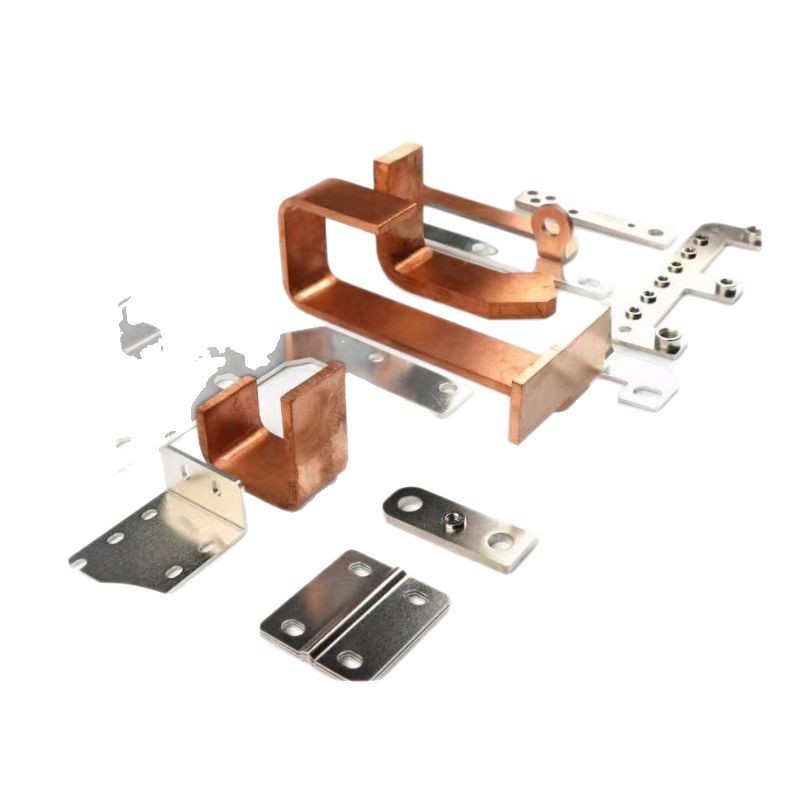

Bus Bar Manufacturing Services

We specialize in manufacturing high-quality bus bars for various industries. Our precision machining capabilities ensure that each bus bar meets the highest standards of performance and reliability.

Expert Bus Bar Manufacturing

With years of experience in bus bar manufacturing, we provide comprehensive solutions for various applications including power distribution, switchgear, and electrical systems. Our advanced manufacturing capabilities allow us to produce bus bars with complex geometries and tight tolerances.

- Precision CNC Machining

- Custom Design & Engineering

- Quality Materials

- Fast Turnaround Time

Our Bus Bar Types

We offer a wide range of bus bar types to meet your specific requirements

Custom Bus Bar

Custom-designed bus bars tailored to your specific requirements and applications.

Copper Bus Bar

High-conductivity copper bus bars for efficient power distribution and electrical applications.

Aluminum Bus Bar

Lightweight and cost-effective aluminum bus bars for various electrical applications.

Battery Bus Bar

Specialized bus bars designed for battery systems and energy storage applications.

Circuit Board Stiffeners

Reinforcement components for printed circuit boards to enhance structural integrity.

Flexible Insulated Bus Bar

Flexible bus bars with insulation for applications requiring movement or vibration resistance.

Insulated Copper Bus Bars

Copper bus bars with electrical insulation for enhanced safety and performance.

Laminated Bus Bar

Multi-layer bus bars for high-current applications with enhanced performance.

Laminated Copper Shunts

Precision current measurement shunts with laminated construction for accurate readings.

Low Voltage Bus Bars for Switchgear

Specialized bus bars designed for low voltage switchgear applications.

Manufacturing Process

Our state-of-the-art manufacturing process ensures precision and quality at every step

Material Selection

Careful selection of high-quality materials based on application requirements.

Precision Machining

Advanced CNC machining for accurate dimensions and surface finish.

Surface Treatment

Specialized surface treatments for enhanced performance and durability.

Quality Control

Rigorous testing and inspection at every stage of production.

Assembly

Precise assembly of components with attention to detail.

Final Testing

Comprehensive final testing to ensure performance and reliability.

Quality Standards

Our commitment to excellence is reflected in our adherence to international quality standards

ISO 9001:2015

Certified quality management system ensuring consistent product quality and customer satisfaction.

IEC Standards

Compliance with international electrical standards for safety and performance.

UL Certification

Products meet UL safety standards for electrical components and systems.

RoHS Compliance

Environmentally responsible manufacturing with restricted hazardous substances.

Frequently Asked Questions

Find answers to common questions about our bus bar manufacturing services

What materials do you use for bus bar manufacturing?

We primarily use copper and aluminum for bus bar manufacturing, but we can also work with other materials based on your specific requirements. Each material has its advantages in terms of conductivity, weight, and cost.

What is the typical lead time for bus bar orders?

Lead times vary depending on the complexity and quantity of the order. Standard orders typically take 2-3 weeks, while custom designs may take longer. We'll provide you with a specific timeline when you place your order.

Do you offer custom bus bar designs?

Yes, we specialize in custom bus bar designs. Our engineering team can work with you to create bus bars that meet your specific requirements in terms of size, shape, material, and performance characteristics.

What quality control measures do you have in place?

We implement rigorous quality control measures throughout the manufacturing process, including material inspection, dimensional verification, conductivity testing, and visual inspection. All our bus bars meet or exceed industry standards.

Ready to Get Started?

Contact us today to discuss your bus bar requirements and get a customized solution for your application.