Expert manufacturing of custom CoCrMo (Cobalt-Chromium-Molybdenum) parts with exceptional biocompatibility, wear resistance, and mechanical properties for medical implants, aerospace components, and industrial applications.

CoCrMo (Cobalt-Chromium-Molybdenum) is a high-performance alloy that combines exceptional mechanical properties with excellent biocompatibility. This versatile material is widely used in medical implants, aerospace components, and industrial applications where strength, corrosion resistance, and wear resistance are critical.

CoCrMo typically contains 60-65% cobalt, 27-30% chromium, 5-7% molybdenum, and small amounts of other elements including nickel, iron, and carbon. This composition provides optimal balance of strength, corrosion resistance, and biocompatibility.

The alloy exhibits excellent density (8.3-8.5 g/cm³), high melting point (1350-1450°C), and superior thermal conductivity. These properties make it ideal for high-temperature applications and precision manufacturing.

CoCrMo offers outstanding tensile strength (800-1200 MPa), yield strength (450-800 MPa), and hardness (25-45 HRC). The material maintains these properties at elevated temperatures and under cyclic loading conditions.

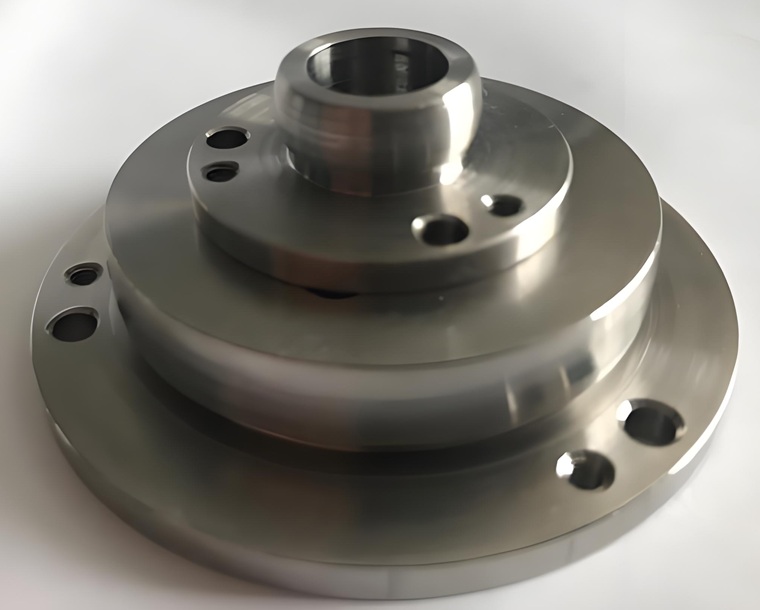

Our specialized manufacturing processes ensure precise CoCrMo parts with superior quality and performance for critical applications.

Advanced CNC machining with specialized tooling for CoCrMo, ensuring tight tolerances and superior surface finishes for medical and aerospace applications.

5-axis CNC machining for complex geometries and intricate features, reducing setup time and improving accuracy for critical components.

High-precision Swiss machining for small, complex parts with excellent dimensional accuracy and surface quality.

Precision wire EDM for intricate shapes and hard-to-reach areas, maintaining material integrity and precision.

Specialized finishing processes including electropolishing, passivation, and mechanical polishing for medical-grade surfaces.

CoCrMo is extensively used in industries requiring high performance, biocompatibility, and reliability.

Hip and knee replacements, dental implants, orthopedic devices, and surgical instruments requiring biocompatibility.

Engine components, turbine blades, high-temperature structural parts, and precision aerospace components.

Wear-resistant components, cutting tools, dies, and high-performance machinery parts.

High-performance engine components, racing parts, and specialized automotive applications.

Corrosion-resistant equipment, valves, and components for aggressive chemical environments.

Comprehensive quality control ensures every CoCrMo part meets the highest industry standards and regulatory requirements.

Full compliance with medical device standards and biocompatibility requirements for implant applications.

Exceptional resistance to wear and abrasion, making it ideal for high-contact applications.

Proven biocompatibility for medical implants and devices requiring long-term tissue contact.

Maintains mechanical properties and dimensional stability at elevated temperatures.

Advanced CNC machining capabilities ensure tight tolerances and superior surface finishes.

Contact us today for expert consultation and competitive pricing on custom CoCrMo parts manufacturing.

Professional CNC machining and custom parts manufacturing services, meeting your precision machining needs with rapid delivery of high-quality components.

© 2025 Partsproto | All rights reserved.