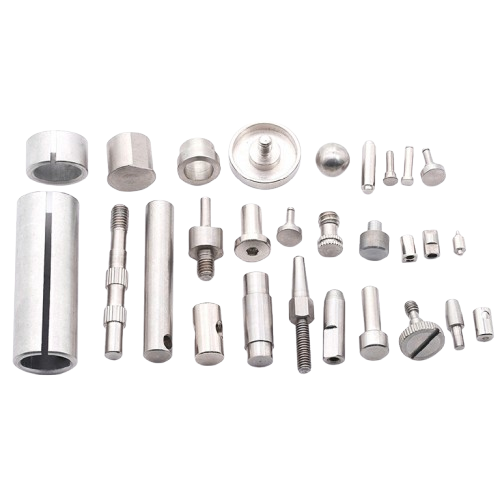

Cost-Effective & Versatile Manufacturing Solutions

Expert manufacturing of mild steel and low carbon steel components with superior weldability, formability, and machinability. Ideal for structural applications and general-purpose engineering.

Choose from our range of mild steel and low carbon steel grades, each optimized for specific manufacturing processes and applications.

Excellent balance of strength, machinability, and cost

Comprehensive manufacturing solutions for mild steel components

Versatile solutions for diverse industrial needs

Lower material and processing costs compared to other metals

Suitable for a wide range of applications and processes

Excellent machinability and fabrication characteristics

Comprehensive quality control for consistent results

Optimized material usage and recycling

Efficient processing and energy conservation

Minimized waste through process optimization

Professional CNC machining and custom parts manufacturing services, meeting your precision machining needs with rapid delivery of high-quality components.

© 2025 Partsproto | All rights reserved.