High-Performance Engineering Solutions

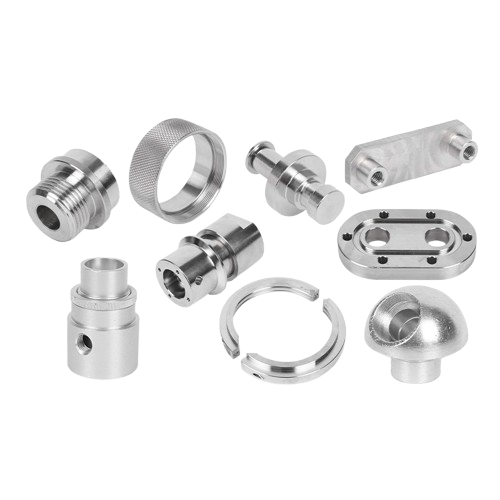

Specialized in manufacturing precision steel alloy components with superior strength, durability, and performance. From tool steel to high-speed steel, we deliver exceptional quality for demanding applications.

Choose from our comprehensive range of high-performance steel alloys, each engineered for specific applications and performance requirements.

State-of-the-art manufacturing capabilities for precision steel alloy components

Multi-axis CNC machining with specialized tooling for hard materials

Comprehensive heat treatment services for optimal material properties

Advanced surface finishing for enhanced performance

Custom steel alloy solutions across diverse industries

Expert guidance in choosing the optimal steel alloy for your application

Comprehensive design support for manufacturability and performance

Rigorous quality assurance throughout the manufacturing process

We work with a wide range of tool steels, high-speed steels, and specialty alloys including D2, A2, M2, H13, and maraging steels. Our metallurgists can help select the optimal grade for your application.

We offer comprehensive heat treatment services including vacuum heat treatment, cryogenic processing, tempering, and stress relieving. All processes are carefully controlled and documented.

Yes, our advanced 5-axis machining centers can handle complex geometries while maintaining tight tolerances. We specialize in difficult-to-machine materials and challenging designs.

We maintain ISO 9001:2015, AS9100D, and IATF 16949 certifications. Our quality system includes comprehensive testing and documentation for full traceability.

We serve various industries including automotive, aerospace, tool and die, and energy sectors. Each industry has specific requirements that we meet through our expertise and quality processes.

Lightweight, high-strength aluminum components with superior corrosion resistance

Excellent electrical conductivity and decorative brass components

High thermal and electrical conductivity copper components

Corrosion-resistant, high-strength stainless steel components

Cost-effective and versatile mild steel components

Lightweight, high-strength titanium components for aerospace and medical

High-performance tool steel components optimized for wear resistance and durability

Ultra-low thermal expansion alloy components for precision applications

Professional CNC machining and custom parts manufacturing services, meeting your precision machining needs with rapid delivery of high-quality components.

© 2025 Partsproto | All rights reserved.