Premium Corrosion-Resistant Engineering Solutions

Leverage our advanced manufacturing capabilities for precision-engineered stainless steel components. From medical grade to marine applications, we deliver exceptional quality with industry-leading corrosion resistance.

Select from our comprehensive range of stainless steel grades, each optimized for specific applications and environments.

Non-magnetic stainless steels with excellent corrosion resistance

Excellent corrosion resistance, good formability

Superior corrosion resistance, especially to chlorides

State-of-the-art manufacturing processes for precision stainless steel components

100% of scrap material recycled

Solar-powered facilities

Closed-loop cooling system

Zero landfill initiative

We work with all major grades including 304/304L, 316/316L, 410, 440C, and 17-4 PH. Each grade is carefully selected based on your application requirements for corrosion resistance, strength, and cost-effectiveness.

Standard lead time is 10-15 business days, with expedited options available for urgent projects. Lead time varies based on complexity, quantity, and current production schedule.

Yes, we provide full material traceability with mill certifications, chemical analysis reports, and mechanical testing results for all stainless steel components.

We offer multiple surface finish options including mirror polish, brushed finish, bead blast, electropolishing, and passivation. Surface roughness can be specified down to Ra 0.1μm.

We maintain rigorous quality control through all manufacturing stages, including incoming material verification, in-process inspection, and final dimensional and surface quality validation.

Yes, our automated manufacturing systems can handle both prototypes and high-volume production runs while maintaining consistent quality and competitive pricing.

Lightweight, high-strength aluminum components with superior corrosion resistance

Excellent electrical conductivity and decorative brass components

High thermal and electrical conductivity copper components

High-performance alloy steel components for demanding applications

Cost-effective and versatile mild steel components

Lightweight, high-strength titanium components for aerospace and medical

High-performance tool steel components optimized for wear resistance and durability

Ultra-low thermal expansion alloy components for precision applications

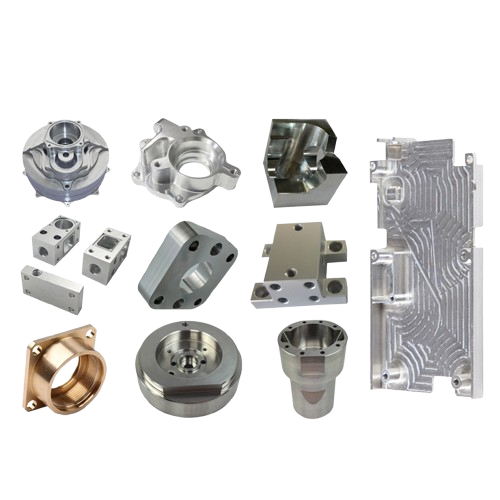

Professional CNC machining and custom parts manufacturing services, meeting your precision machining needs with rapid delivery of high-quality components.

© 2025 Partsproto | All rights reserved.