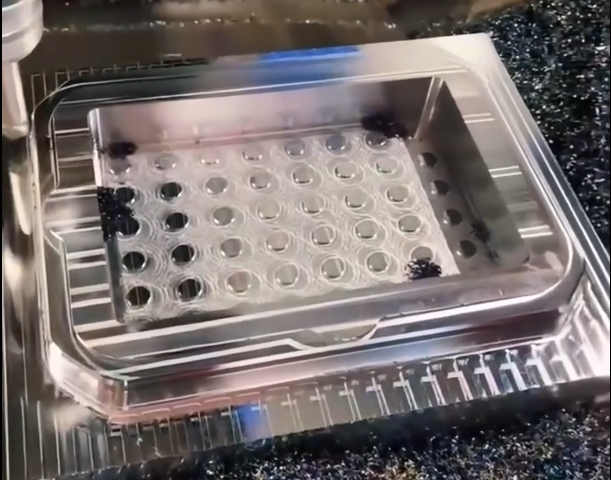

Professional injection molding services for acrylic (PMMA) materials. We specialize in high-volume production of optical-grade components with superior clarity, dimensional accuracy, and cost-effective manufacturing for various industries.

Discover the benefits of injection molding for acrylic components:

Mass production with consistent quality and efficiency

Intricate designs with precise dimensional control

Optical-grade surfaces with minimal post-processing

Minimal waste with optimized material usage

Our advanced injection molding services for acrylic materials:

High-volume production with precision control

Hollow parts with reduced material usage

Metal inserts integrated into acrylic parts

Injection molded acrylic parts for diverse applications:

Enhance the appearance and functionality of your acrylic parts:

Comprehensive quality control ensures perfect injection molded parts:

Detailed specifications for our acrylic injection molding services:

Our comprehensive injection molding process ensures quality and efficiency

Drying and preheating of PMMA pellets to optimal moisture content

High-pressure injection of molten acrylic into precision molds

Controlled cooling and automated part ejection from molds

Comprehensive quality control and dimensional verification

Common questions about acrylic injection molding:

Get a free quote for your custom acrylic injection molding project. Our team of experts is ready to help you achieve high-volume production with superior quality.

Professional CNC machining and custom parts manufacturing services, meeting your precision machining needs with rapid delivery of high-quality components.

© 2025 Partsproto | All rights reserved.